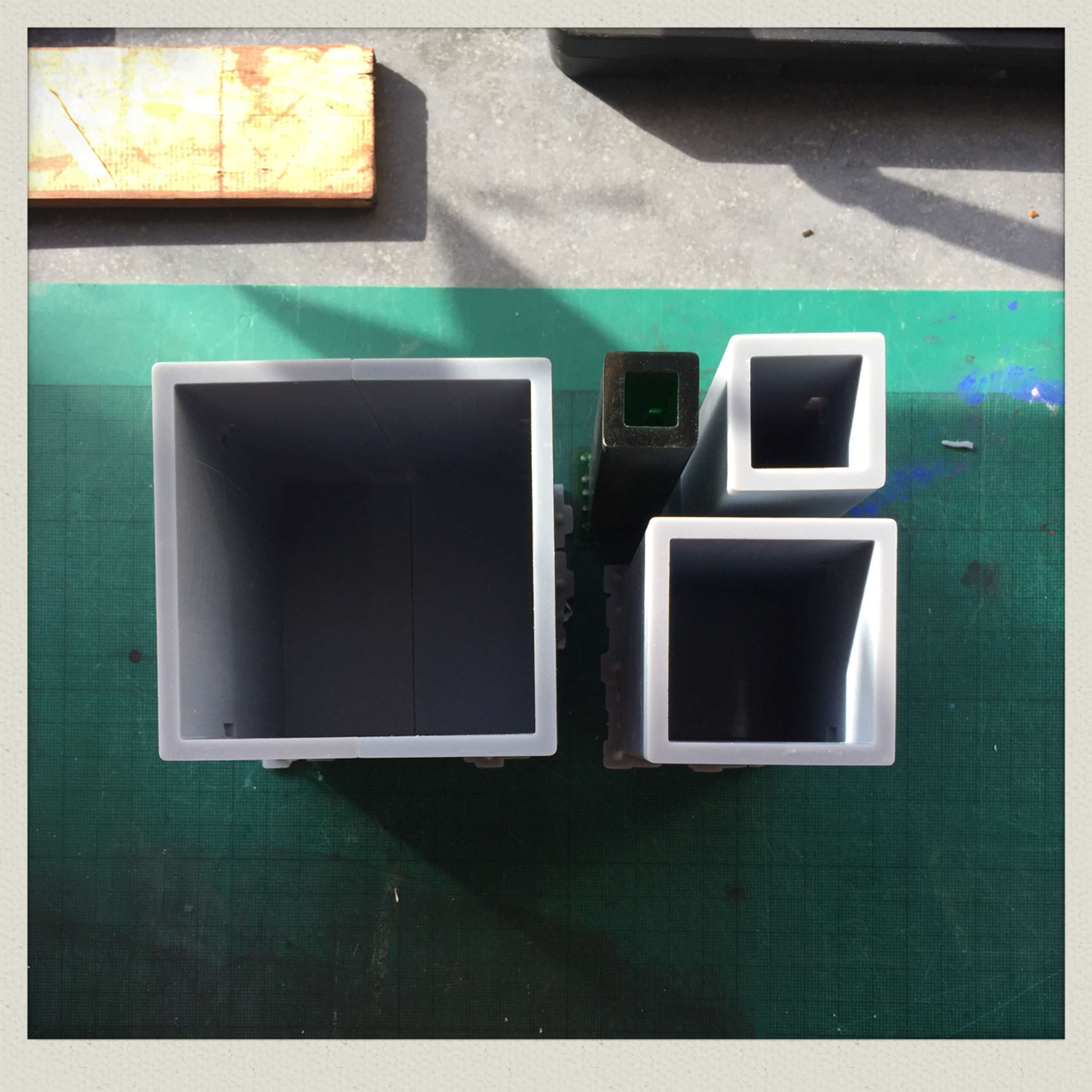

JESMONITE CASTING POTS

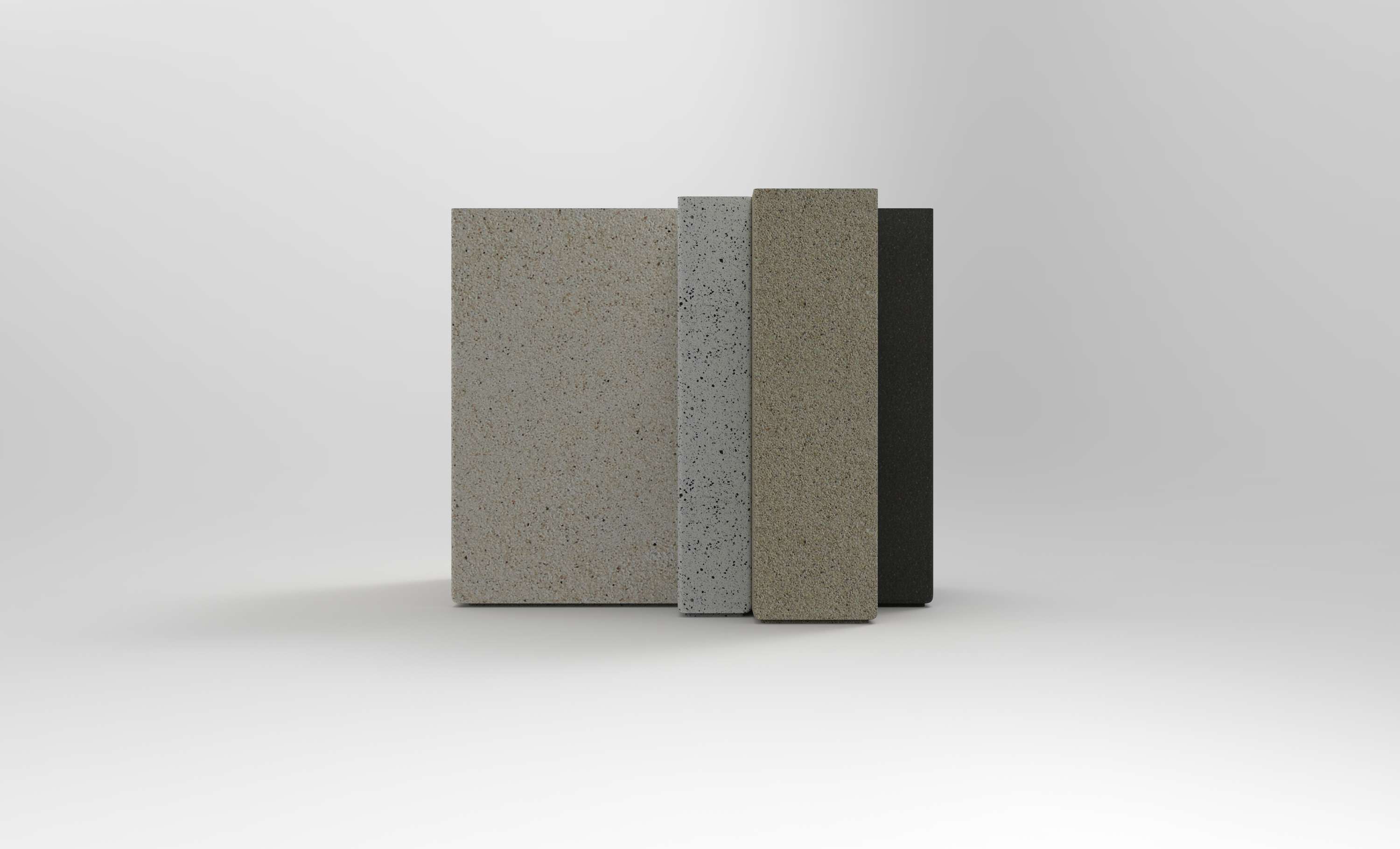

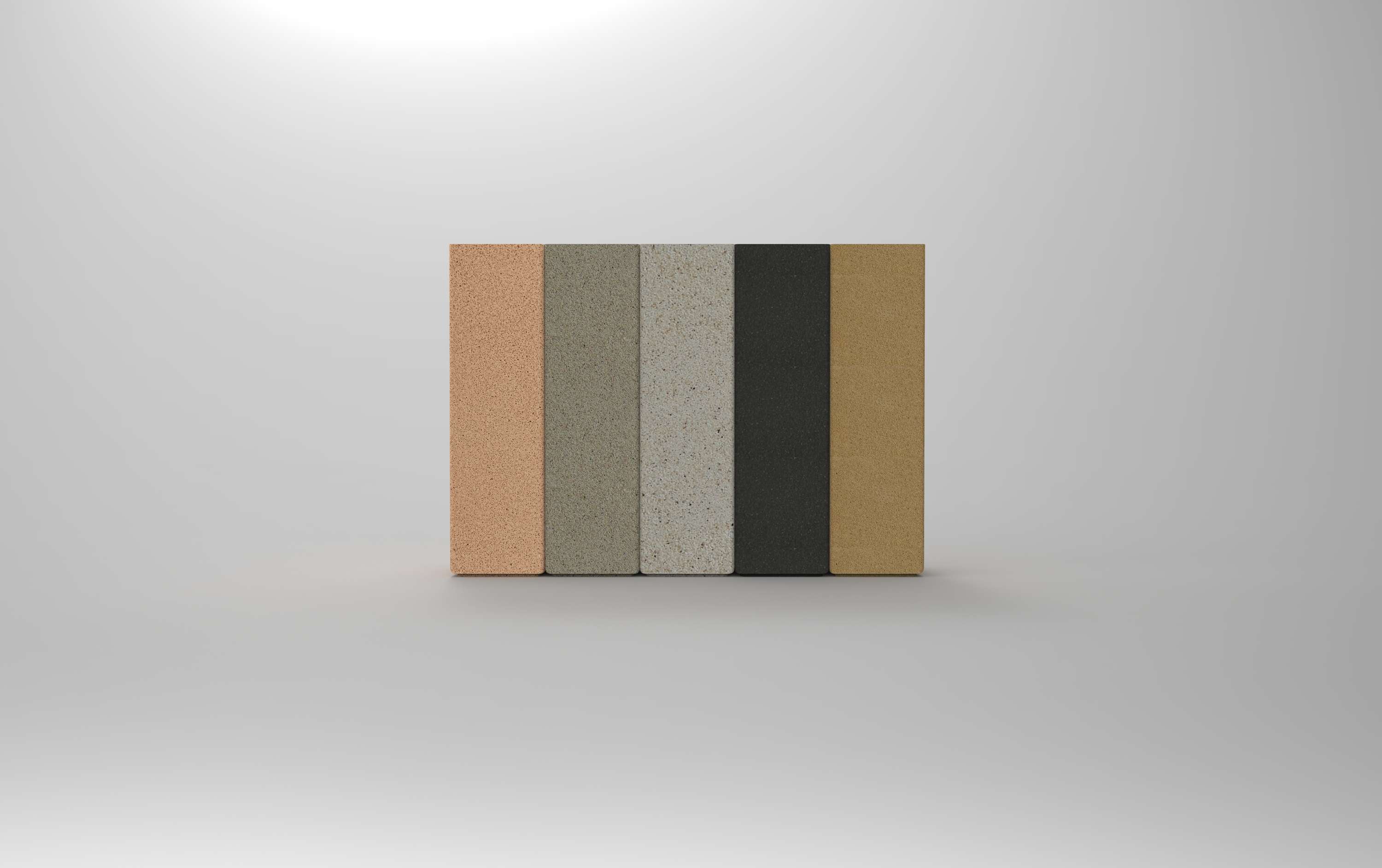

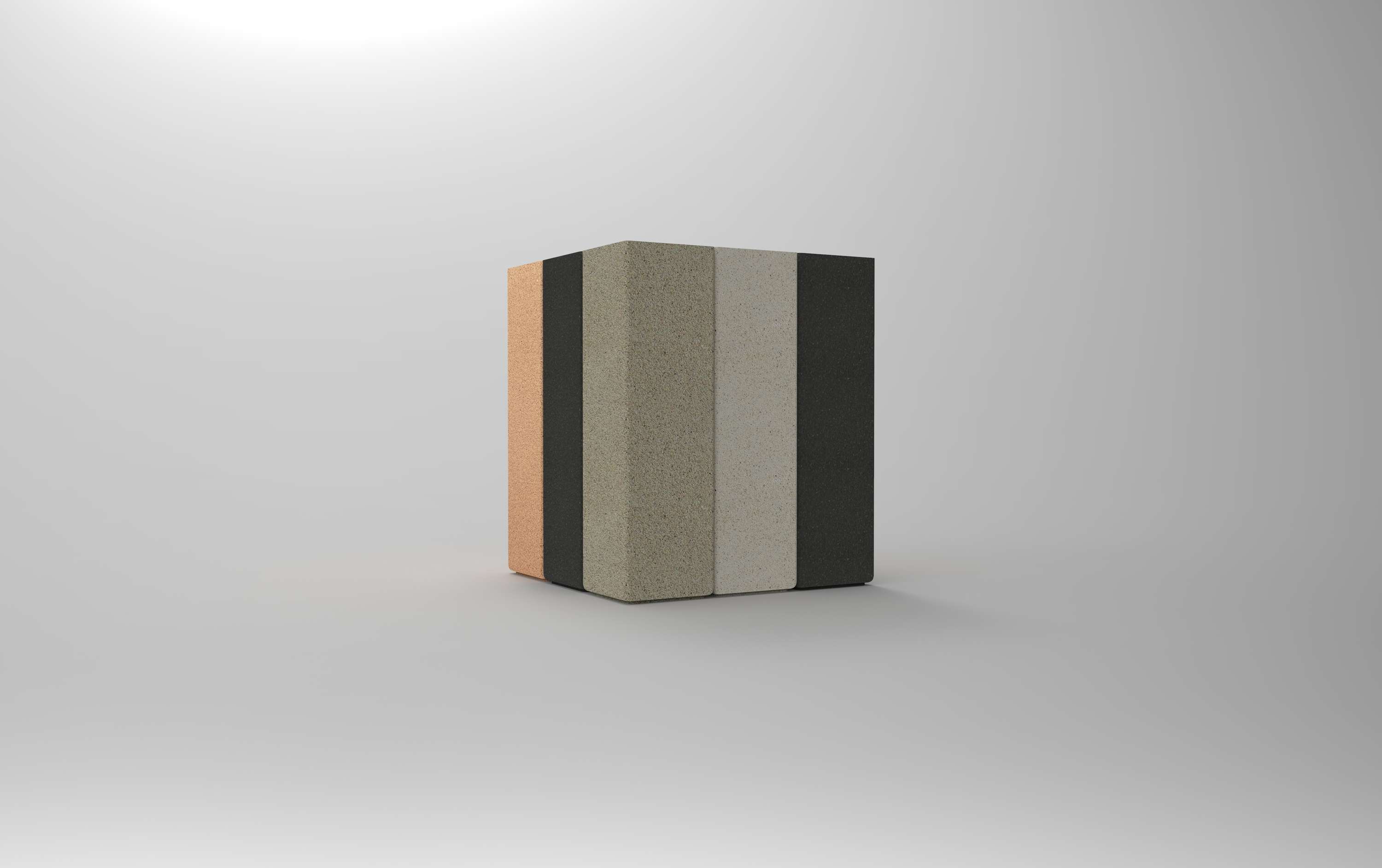

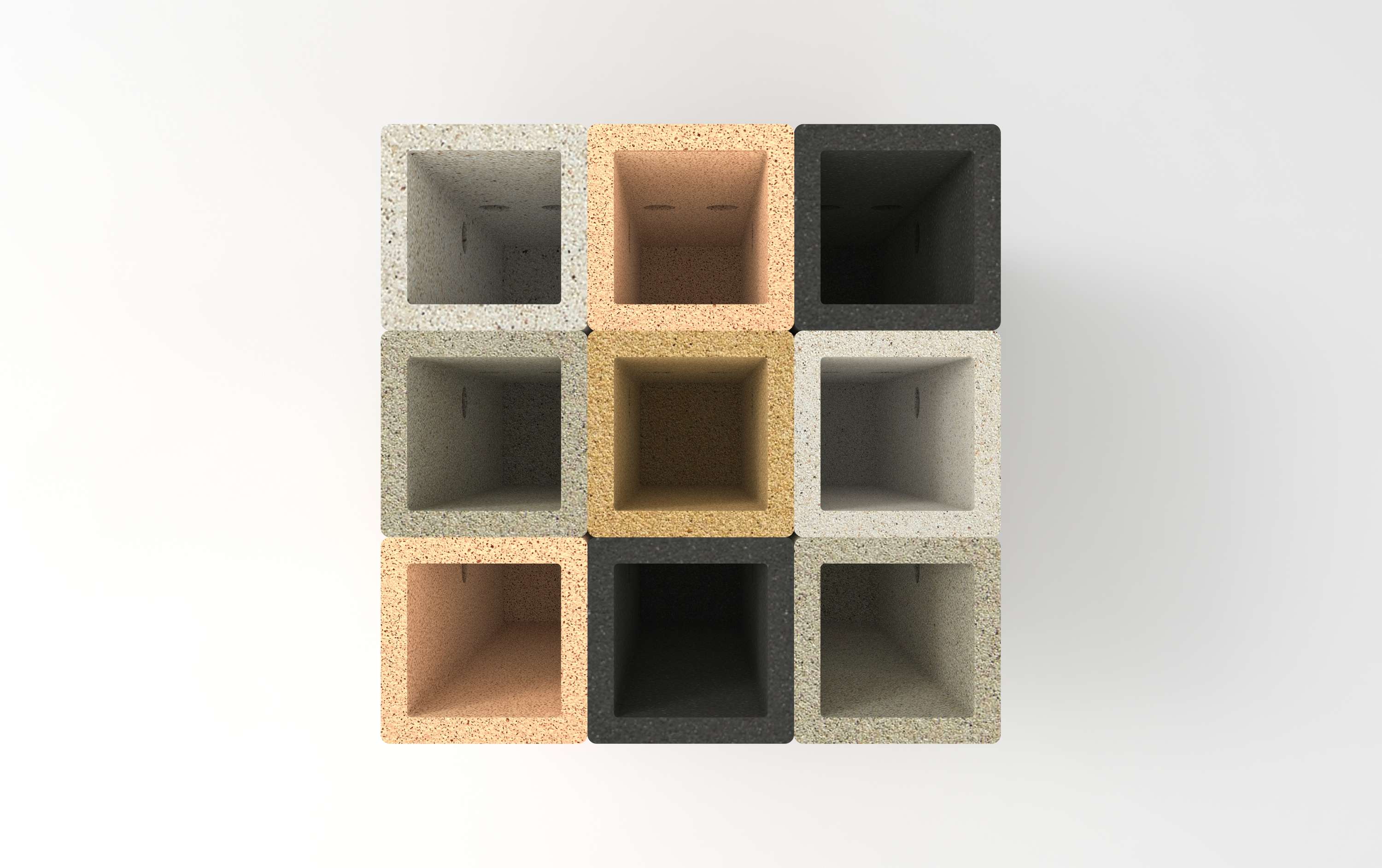

The Jesmonite casting pots are a personal project which uses cutting edge technology to serve craft processes. The overall pot dimensions follow the Fibonacci Sequence in its classic shape such that each number is the sum of the two preceding ones. Strongly linked to the Golden Ratio, the proportion is recognised for striving for beauty and completeness in the realms of both nature and art (Zeiving 1854). Each pot is equipped with neodymium magnets at different corners so the pots layout can be customised as desired, bringing modularity to the product. The pots are cast in Jesmonite AC730, used for its resistance to impacts and its colour range. Acid Eth is sometimes used to give the outside surfaces a rough finish. The square pot base models are printed by DLP in order to obtain sharp dimensions and geometry, while all the tooling and jigs are printed by FDM in PLA for cost effectiveness and size restriction. The tooling for the silicone mould is composed of: A Base that locates the base model in the centre and that will level the silicone mould stepping surface. A Wall that defines the silicone external wall thicknesses. An Insert that defines the wall thicknesses of the pots inside and that includes the plots for the magnets. The silicone used is a RTV silicone of Shore A 25. A silicone fluid is added to the catalyst to allow detailing the thin walls as well as the bottom shadow line. The Jig used in the casting phase ensures that the silicone mould walls are in the right position in order to ensure pot geometry.